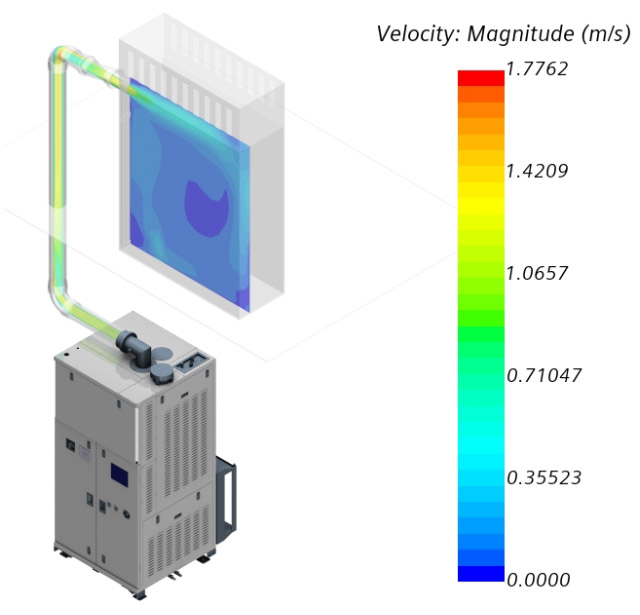

It is a system that adjusts the air temperature, humidity and air current in a way best conforming to the intention of the user.

To control the temperature/humidity environment of the coater and developer equipment for photolithography and of the PR throughout the semiconductor manufacturing process

| Control Spec. | Temp. | THC | S.V ± 0.1℃ |

| Humid. | S.V ± 0.5% | ||

| Temp. | CHR | S.V ± 0.1℃ |

| Control Spec. | Temp. | THC | S.V ± 0.1℃ |

| Humid. | S.V ± 0.5% |

It is a system that controls the humidity within the chamber by cooling down the indoor air.

To control the humidity of the etch and wet equipment throughout the semiconductor manufacturing process

| Temperature/humidity control performance |

|

|---|

It is a system that adjusts the temperature of the liquid(constant-temperature water) in a way suitable for user requirements.

To control the motor, flow and water temperature of the coater and developer equipment for photolithography throughout the semiconductor manufacturing process

|

|

|